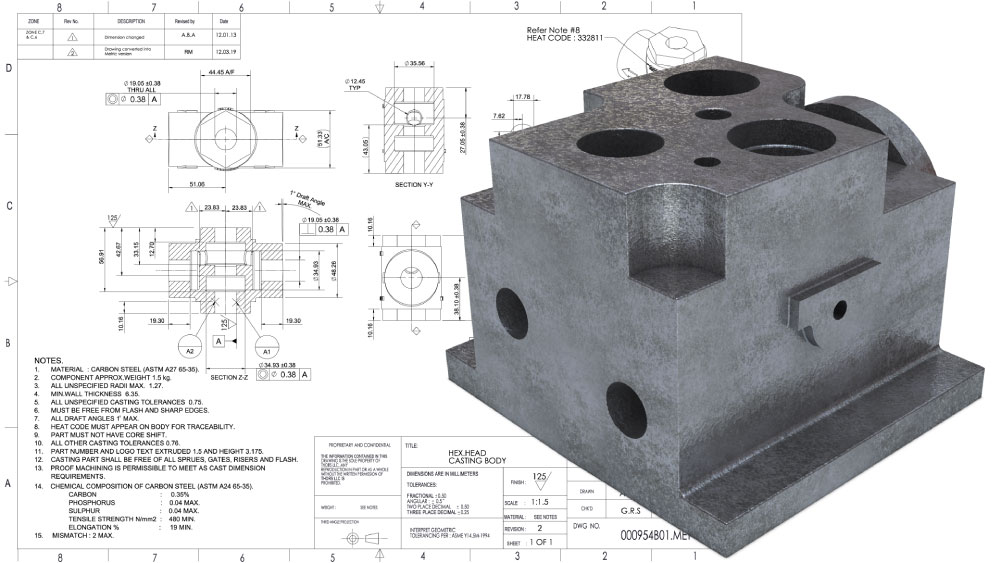

Casting Drawing

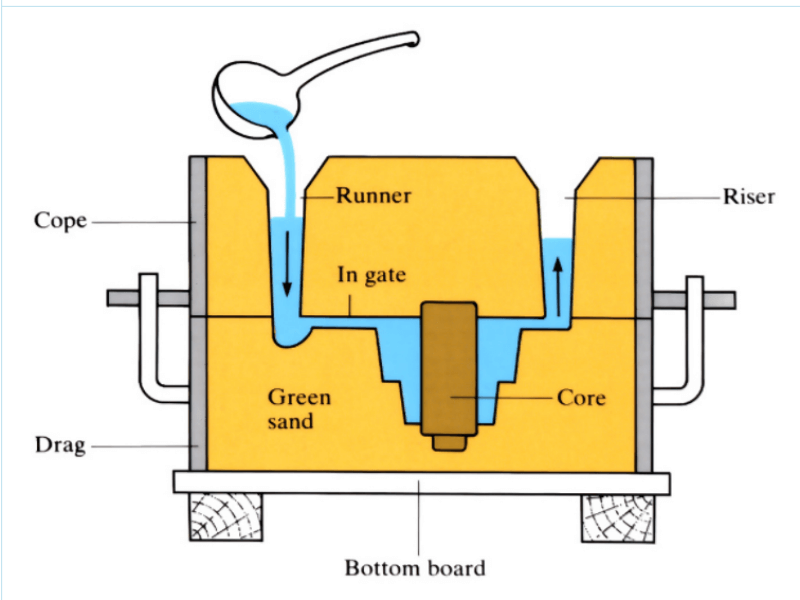

Casting Drawing - The parting line is the line around a casting component where two molds meet each other. If you are stuck with a print without casting datums and must replicate the part, then you should look at a couple of things. Web castings, forgings, and molded parts. Web the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the casting is taken out by ejecting or by breaking the mold. Web comprehensive digital design solution was provided to the client with 3d models and detailed manufacturing drawings for casting components with accurate information on dimensions and tolerances. For example, a pose that a model takes is bound to change to some degree as he or she settles into it. Sand casting is the most popular casting process employed in industry. The drawing should define those requirements as completely and specifically as possible, since anything not defined on the drawing is left open to your supplier's discretion. Casting covers a variety of parts and is useful in many industries from creating highly stylized claws to standard automotive parts. Web this chapter focuses on engineering drawings for casting production, providing information on machining and casting drawings and machining and tooling references.

Describe the importance of the notes section of a casting drawing and the different types of notes. Presented in thors’ highly visual and interactive learning format, this course will help employees understand and interpret engineering drawings for castings. In this tutorial, one of our elite application engineers shows his tips and tricks for modeling castings. For example, a pose that a model takes is bound to change to some degree as he or she settles into it. How does 'next level chef work? To see how datum planes and points are placed. Web comprehensive digital design solution was provided to the client with 3d models and detailed manufacturing drawings for casting components with accurate information on dimensions and tolerances. Naturally bonded and synthetic sands. It is an opportunity to become familiar with the figure drawing process before facing the challenges of drawing a model. The parting line is the line around a casting component where two molds meet each other.

If you are stuck with a print without casting datums and must replicate the part, then you should look at a couple of things. Web casting engineering by rapidprotocasting. The casting process can produce everything from art pieces to engine parts. Web what is a draft angle on an engineering drawing for castings? There are two general types of sand: Web to assign dimensions and tolerances to a part that is produced as a casting involves consideration of function and fit of the finished part, allowances for machining operations involved in producing the finished part, and production requirements such as. To see how datum planes and points are placed. Web an engineering drawing, such as those for your cast part and machined part, is a set of requirements for a finished part condition. Sand casting is the most popular casting process employed in industry. The parting line is the line around a casting component where two molds meet each other.

How To Dimension A Casting Drawing

Describe the importance of the notes section of a casting drawing and the different types of notes. For example, a pose that a model takes is bound to change to some degree as he or she settles into it. 12, 2023, while season 3 debuted on jan. Web what is a draft angle on an engineering drawing for castings? Since.

Creating a Machining Drawing for a Cast Part YouTube

Identify the distinct characteristics that are included in a casting drawing. Web over time casting designers have come to find the value in casting datums and for the most part they are included with new designs. Differentiate the various symbols commonly associated with a casting drawing. Web the casting design process is a manufacturing process where molten material like a.

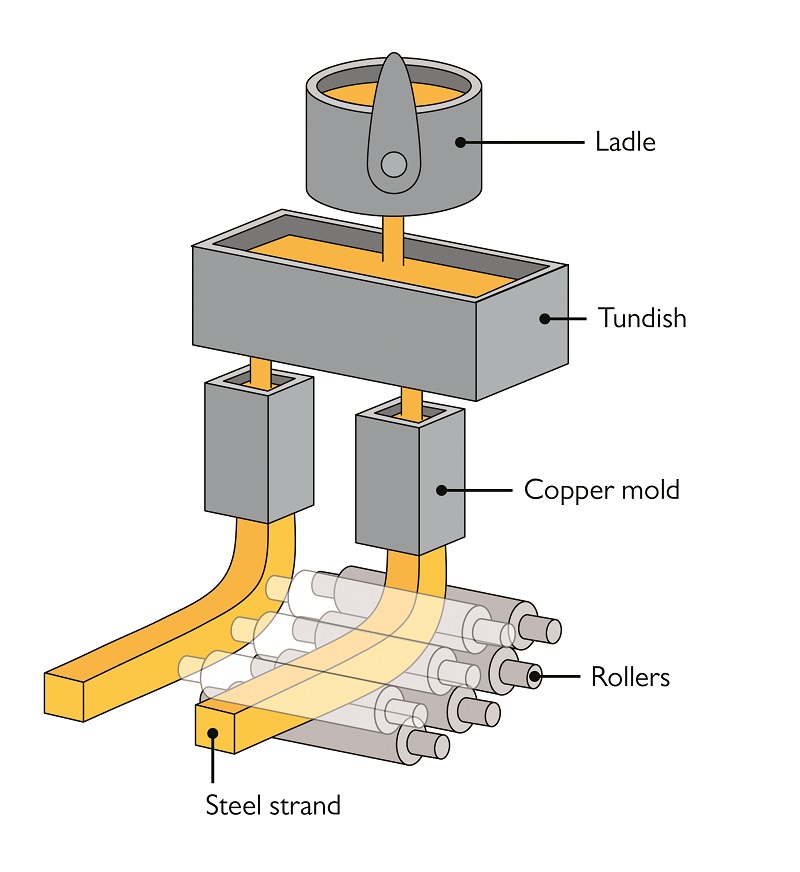

Metal Casting Process Metal casting, Metal casting process, Metal

Web over time casting designers have come to find the value in casting datums and for the most part they are included with new designs. Since i have to soon begin my own drawing on a hollow circular part with an odd shape flange. The casting process can produce everything from art pieces to engine parts. To see how datum.

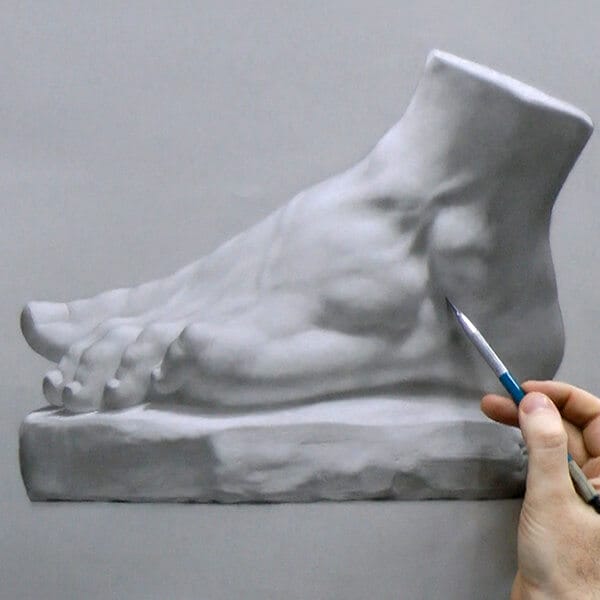

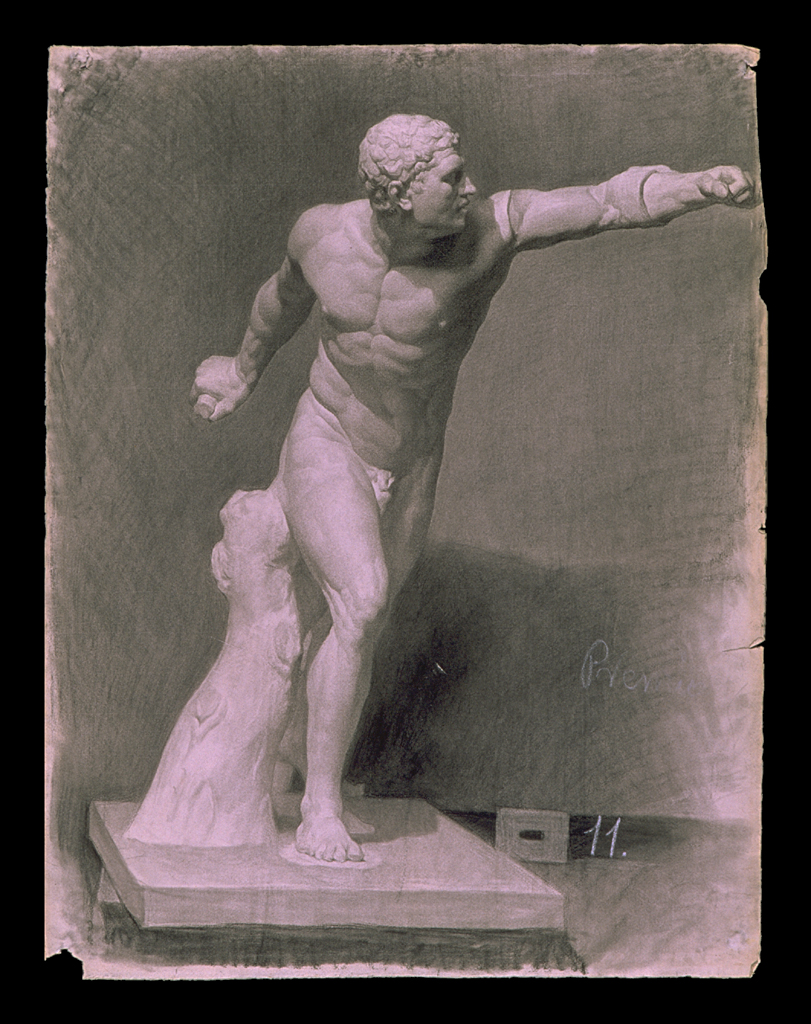

All about Academic Cast Drawing The Ultimate Guide

The casting process can produce everything from art pieces to engine parts. As head of partnerships, i help businesses find the best talent for their influencer campaigns, photo shoots, and film productions. Web in this video i discuss the requirements of a part drawing created for the machining of a cast part. Web 1 of 3 |. Sand casting molds.

Cast Drawing Video with Instructional Commentary Vitruvian Fine Art

Sand casting is the most popular casting process employed in industry. In this tutorial, one of our elite application engineers shows his tips and tricks for modeling castings. The casting designer’s intent is to provide enough slot size and slot position to enable the casting to be cast in sand. Identify the distinct characteristics that are included in a casting.

All about Academic Cast Drawing The Ultimate Guide

Web castings, forgings, and molded parts. How does 'next level chef work? Web comprehensive digital design solution was provided to the client with 3d models and detailed manufacturing drawings for casting components with accurate information on dimensions and tolerances. Engineering drawing and related documentation practices. Web an engineering drawing, such as those for your cast part and machined part, is.

Optimizing the Continuous Casting Process with Simulation COMSOL Blog

Engineering drawings use standardised language and symbols. To see how datum planes and points are placed. If you are stuck with a print without casting datums and must replicate the part, then you should look at a couple of things. As head of partnerships, i help businesses find the best talent for their influencer campaigns, photo shoots, and film productions..

All about Academic Cast Drawing The Ultimate Guide

Web in this video i discuss the requirements of a part drawing created for the machining of a cast part. Naturally bonded and synthetic sands. This designer did a good job using gd&t for the design intent. Web what is a draft angle on an engineering drawing for castings? Sand casting molds use silica based sands.

Engineering Drawings for Castings Course

8, 2022, at southside elementary school in huntington, w.va. Engineering drawing and related documentation practices. Web best practices for modeling castings in solidworks. Web casting engineering by rapidprotocasting. The casting process can produce everything from art pieces to engine parts.

Handbook The Ultimate Guide to Metal Casting 2024 Updated

Web casting is the process of pouring liquid metal into a mold, where it cools and solidifies. That can be controlled better synthetic sand and, is the most common used by foundries. Web casting engineering by rapidprotocasting. Web 1 of 3 |. The parting line is the line around a casting component where two molds meet each other.

Web Castings, Forgings, And Molded Parts.

Web i'm looking for link(s) to show examples of sand casting drawings and its corresponding machine drawing. Web the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and allowed to cool or solidify within the printed mold. Since i have to soon begin my own drawing on a hollow circular part with an odd shape flange. Web casting engineering by rapidprotocasting.

Web An Engineering Drawing Is A Subcategory Of Technical Drawings.

The casting designer’s intent is to provide enough slot size and slot position to enable the casting to be cast in sand. Differentiate the various symbols commonly associated with a casting drawing. Cast drawing wonderfully bridges still life and figure drawing. Identify the distinct characteristics that are included in a casting drawing.

If You Are Stuck With A Print Without Casting Datums And Must Replicate The Part, Then You Should Look At A Couple Of Things.

Web what is a draft angle on an engineering drawing for castings? Web comprehensive digital design solution was provided to the client with 3d models and detailed manufacturing drawings for casting components with accurate information on dimensions and tolerances. Web engineering drawings for castings elaborates on the fundamental terminology associated with engineering drawings used when casting a product. That can be controlled better synthetic sand and, is the most common used by foundries.

How Does 'Next Level Chef Work?

It is an opportunity to become familiar with the figure drawing process before facing the challenges of drawing a model. Sand casting molds use silica based sands. Voters are casting primary ballots in west virginia, a heavily republican state that’s filled with open seats this election year, drawing multiple competitive primaries. Naturally bonded and synthetic sands.