Temperature Mapping Protocol Template

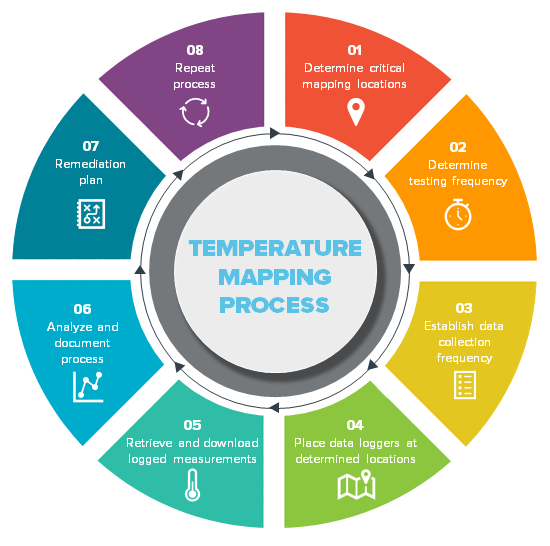

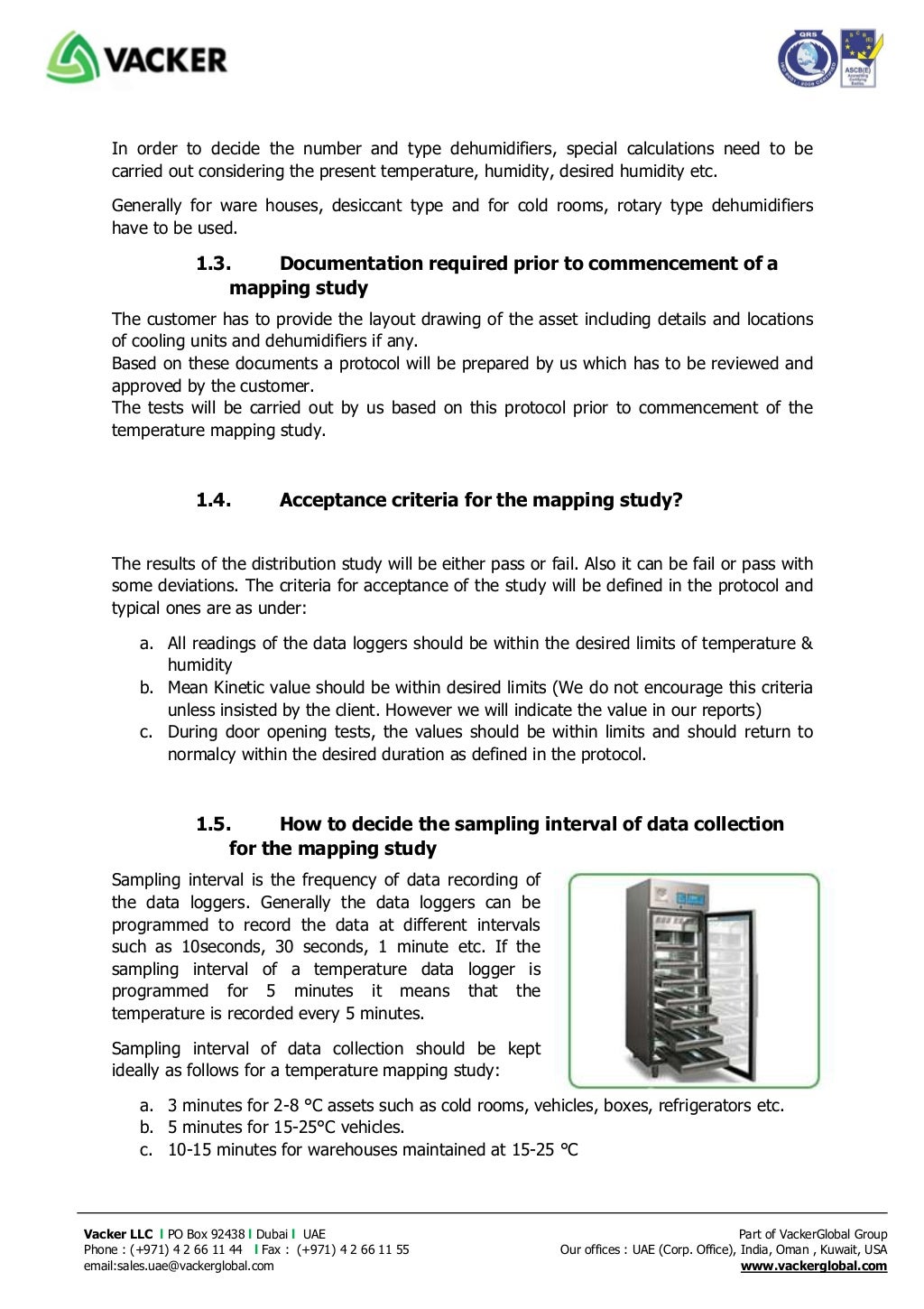

Temperature Mapping Protocol Template - • determine a validation schedule. Web temperature mapping protocols will vary between the individuals unique requirements. • create change control protocols so it’s clear when changes such as maintenance, new construction, and reconfiguration of racks will require revalidation. Whilst this guide is not exhaustive, it will give you an idea of the questions you should be asking yourself when carrying out a. 2.3.7 qualification report template 17 2.3.8 approval process 18 2.4 installation qualification 18 2.4.1 identifying critical components 19 2.4.2 checking installed systems, subsystems and components 19. If you have questions about cold storage mapping, please contact your thermo fisher sales or service representative. Temperature mapping of storage areas. Approval page and change control history Web 2.3 qualification protocols 15 2.3.1 approval page and change control history 15. Web a temperature or humidity excursion occurs.

Web thermal mapping protocol template [protocol number: Approval page and change control history b. • determine a validation schedule. 2.3.7 qualification report template 17 2.3.8 approval process 18 2.4 installation qualification 18 2.4.1 identifying critical components 19 2.4.2 checking installed systems, subsystems and components 19. Web understand what cold storage temperature mapping entails. This information should serve as a starting point as you implement your temperature mapping process and reinforce some of the basics for those who do it every day. However, the process does not need to be complicated. Web a temperature or humidity excursion occurs. Temperature mapping of storage areas. A temperature mapping exercise is required for any space allocated for the storage and handling of products with a specified labelled storage temperature.

In this month’s blog, we look at how to do temperature mapping. Annexes as needed, including templates for the mapping report. 2.3.7 qualification report template 17 2.3.8 approval process 18 2.4 installation qualification 18 2.4.1 identifying critical components 19 2.4.2 checking installed systems, subsystems and components 19. Web a temperature or humidity excursion occurs. Temperature mapping of storage areas. This information should serve as a starting point as you implement your temperature mapping process and reinforce some of the basics for those who do it every day. • create change control protocols so it’s clear when changes such as maintenance, new construction, and reconfiguration of racks will require revalidation. • specify the management approval process, especially for adverse events such as temperature deviations. Web 2.2 the mapping protocol 11 2.2.1 approval page and change control history 11 2.2.2 acronyms and glossary 12 2.2.3 description and rationale 12 2.2.4 scope 12 2.2.5 objectives 13 2.2.6 methodology 14 2.2.7 mapping report template 18 2.3 conducting the mapping exercise 18 2.4 analysing the data and preparing the mapping report 18 Web temperature mapping protocols will vary between the individuals unique requirements.

Temperature Mapping 7 Day Labcold

Temperature mapping establishes the temperature distribution within the zonebeing mapped and it locates hot and cold spots. Web temperature mapping protocols will vary between the individuals unique requirements. Web the mapping protocol should contain the following sections: • create change control protocols so it’s clear when changes such as maintenance, new construction, and reconfiguration of racks will require revalidation. A.

Temperature Mapping Validation Services Anova

Approval page and change control history 2.3.7 qualification report template 17 2.3.8 approval process 18 2.4 installation qualification 18 2.4.1 identifying critical components 19 2.4.2 checking installed systems, subsystems and components 19. Web the mapping protocol should contain the following sections: If you have questions about cold storage mapping, please contact your thermo fisher sales or service representative. A temperature.

temperaturemappingstudyprotocolprocedure.pdf Refrigeration

If you have questions about cold storage mapping, please contact your thermo fisher sales or service representative. 2.3.7 qualification report template 17 2.3.8 approval process 18 2.4 installation qualification 18 2.4.1 identifying critical components 19 2.4.2 checking installed systems, subsystems and components 19. Whilst this guide is not exhaustive, it will give you an idea of the questions you should.

Temperature Mapping Services IntroTech, the Cold Chain specialist

Temperature mapping of storage areas. Xxxxxxxx] dfasdf dfasdf you can buy a full version of this template in ms word format that shall be completely editable, ready to use according to your needs, visiting: Approval page and change control history Web detailed procedure and guidelines on temperature mapping study & qualification of cold rooms, warehouses, vans, trucks, reefers, refrigerators &.

WHO Guidelines Temperature mapping of storage areas free PDF

Web detailed procedure and guidelines on temperature mapping study & qualification of cold rooms, warehouses, vans, trucks, reefers, refrigerators & boxes for pharmaceutical industry temperature mapping study and temperature qualification study are carried out generally in. If you have questions about cold storage mapping, please contact your thermo fisher sales or service representative. Web understand what cold storage temperature mapping.

Temperature mapping study & qualification protocol procedure

Web 2.2 the mapping protocol 11 2.2.1 approval page and change control history 11 2.2.2 acronyms and glossary 12 2.2.3 description and rationale 12 2.2.4 scope 12 2.2.5 objectives 13 2.2.6 methodology 14 2.2.7 mapping report template 18 2.3 conducting the mapping exercise 18 2.4 analysing the data and preparing the mapping report 18 If you have questions about cold.

Warehouse Temperature Mapping Protocol map Resume Examples Wk9y6EE0Y3

Web detailed procedure and guidelines on temperature mapping study & qualification of cold rooms, warehouses, vans, trucks, reefers, refrigerators & boxes for pharmaceutical industry temperature mapping study and temperature qualification study are carried out generally in. 2.3.7 qualification report template 17 2.3.8 approval process 18 2.4 installation qualification 18 2.4.1 identifying critical components 19 2.4.2 checking installed systems, subsystems and.

Temperature Mapping of Storage Areas for Pharmaceuticals Incepbio

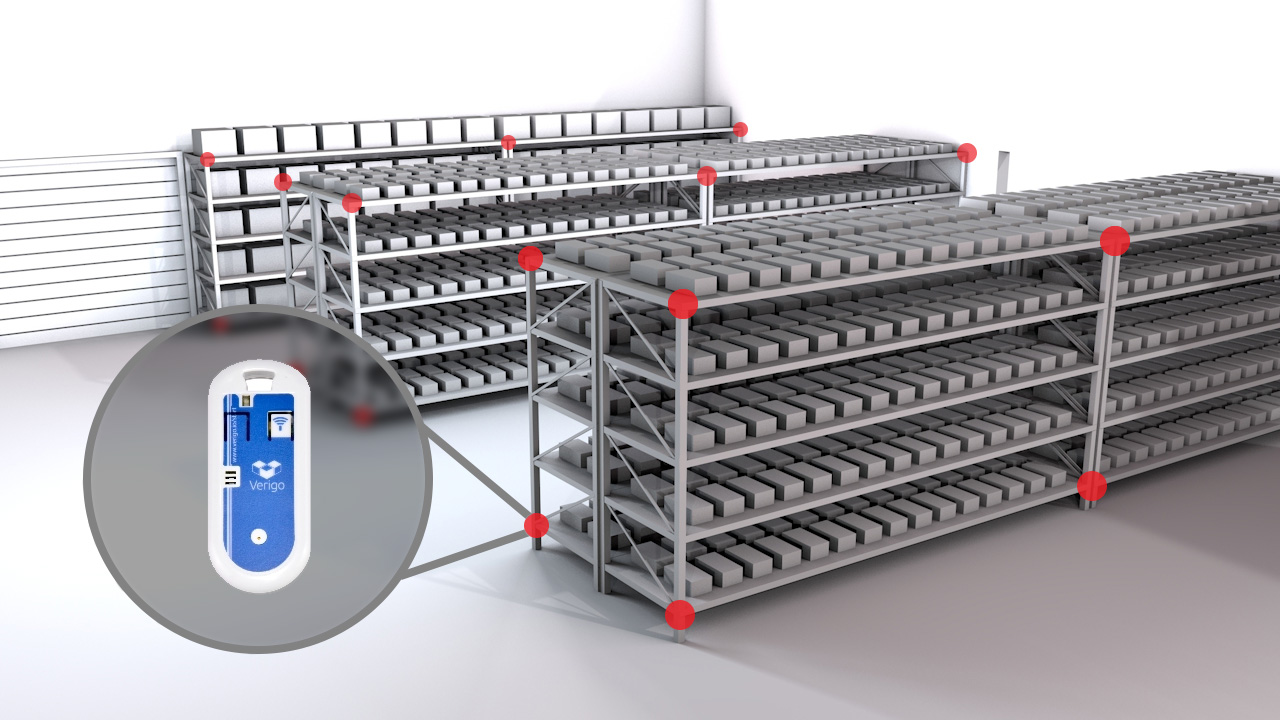

Planning, including determining optimal sensor type and placement, and how the. 2.3.7 qualification report template 17 2.3.8 approval process 18 2.4 installation qualification 18 2.4.1 identifying critical components 19 2.4.2 checking installed systems, subsystems and components 19. • determine a validation schedule. Annexes as needed, including templates for the mapping report. Web the mapping protocol should contain the following sections:

Temperature Mapping Qualification Protocol for Refrigerator

Web thermal mapping protocol template [protocol number: Planning, including determining optimal sensor type and placement, and how the. Approval page and change control history Web the mapping protocol should contain the following sections: A temperature mapping exercise is required for any space allocated for the storage and handling of products with a specified labelled storage temperature.

Apoteker Oke Temperature Mapping

Web detailed procedure and guidelines on temperature mapping study & qualification of cold rooms, warehouses, vans, trucks, reefers, refrigerators & boxes for pharmaceutical industry temperature mapping study and temperature qualification study are carried out generally in. Temperature mapping establishes the temperature distribution within the zonebeing mapped and it locates hot and cold spots. Annexes as needed, including templates for the.

Web 2.3 Qualification Protocols 15 2.3.1 Approval Page And Change Control History 15.

Web the mapping protocol should contain the following sections: Temperature mapping establishes the temperature distribution within the zonebeing mapped and it locates hot and cold spots. However, the process does not need to be complicated. • specify the management approval process, especially for adverse events such as temperature deviations.

This Information Should Serve As A Starting Point As You Implement Your Temperature Mapping Process And Reinforce Some Of The Basics For Those Who Do It Every Day.

Web understand what cold storage temperature mapping entails. Web detailed procedure and guidelines on temperature mapping study & qualification of cold rooms, warehouses, vans, trucks, reefers, refrigerators & boxes for pharmaceutical industry temperature mapping study and temperature qualification study are carried out generally in. Approval page and change control history b. Xxxxxxxx] dfasdf dfasdf you can buy a full version of this template in ms word format that shall be completely editable, ready to use according to your needs, visiting:

Whilst This Guide Is Not Exhaustive, It Will Give You An Idea Of The Questions You Should Be Asking Yourself When Carrying Out A.

Planning, including determining optimal sensor type and placement, and how the. Web 2.2 the mapping protocol 11 2.2.1 approval page and change control history 11 2.2.2 acronyms and glossary 12 2.2.3 description and rationale 12 2.2.4 scope 12 2.2.5 objectives 13 2.2.6 methodology 14 2.2.7 mapping report template 18 2.3 conducting the mapping exercise 18 2.4 analysing the data and preparing the mapping report 18 Web thermal mapping protocol template [protocol number: A temperature mapping exercise is required for any space allocated for the storage and handling of products with a specified labelled storage temperature.

• Create Change Control Protocols So It’s Clear When Changes Such As Maintenance, New Construction, And Reconfiguration Of Racks Will Require Revalidation.

If you have questions about cold storage mapping, please contact your thermo fisher sales or service representative. In this month’s blog, we look at how to do temperature mapping. Annexes as needed, including templates for the mapping report. Web a temperature or humidity excursion occurs.